TORONTO, Sept. 25, 2024 (GLOBE NEWSWIRE) — Giyani Metals Corp. (TSXV:EMM, GR:A2DUU8) (“Giyani” or the “Company“), developer of the K.Hill Battery-Grade Manganese Project in Botswana (“K.Hill” or “the Project“), is pleased to provide an update on construction of the Demonstration Plant (“Demo Plant“) where construction is continuously moving forwards, a video showing this with CEO Charles FitzRoy, Group Process Engineer Justin Taylor and Lead Process Engineer Desiree Meyer will be released tomorrow September 26, 2024.

Highlights:

- The Demo Plant in Johannesburg is moving into the detailed fit-out phase, with all modular process skids (“Process Modules“) now installed. Cabling and piping work has commenced to connect the Process Modules in preparation for commissioning.

- As well as progress at the Demo Plant, concurrent metallurgical test-work is underway at CM Solutions, a metallurgical consultancy and laboratory in Johannesburg, to optimize the flowsheet. Giyani is focussed on reducing reagent use where possible and has evolved its process to remove hydrofluoric acid (“HF“). This is an important development, as it eliminates the requirement to store and handle potentially hazardous HF at both the Demo Plant and the planned Commercial Site.

- In support of the Demo Plant operations, Minopex, a DRA Global Company [JSE:DRA], have now been engaged to operate the Demo Plant. Minopex is a world-renowned group who have operated and maintained approximately 50 plants, and commissioned and ramped-up over 90 globally. Giyani is pleased to have gained a reputable partner with relevant expertise to advance the project.

- Simulation test-work continues on the Yokogawa Distributed Control System (“DCS“) software that will be used to control the Demo Plant, which will operate as a continuous process flow, rather than batch basis.

- The continuous process flow of the Demo Plant is a significant advantage for Giyani, as it enables the team to operate the plant at steady state and confirm the ability to produce consistent specification battery-grade manganese (HPMSM). By demonstrating this ability to potential offtake partners, Giyani can satisfy their requirements for a consistent product specification and production rate.

- As the Demo Plant is a direct copy of the proposed Commercial Plant, albeit at smaller scale, Giyani will better understand how the proposed Commercial Plant (in Botswana) will respond, in advance of construction, commissioning and ramp-up. This enables further optimisation of the engineering design in parallel with the Definitive Feasibility Study (“DFS“) which is underway, and due to complete in 2025.

- The Demo Plant remains on track for commissioning and production of up to 600kg a day of battery-grade manganese (HPMSM) in Q4 2024. HPMSM produced from the Demo Plant will be provided to offtakers for testing and qualification. Giyani will keep the market updated of progress at the Demo Plant and all other developments.

Charles FitzRoy, President and CEO of the Company, commented:

“Giyani is entering a metamorphic stage on its trajectory as a battery metals developer, with the first production of battery-grade manganese on track for delivery in Q4 this year. The Demo Plant, to our knowledge, is the largest of its kind in the world, and offers Giyani many advantages that would not be available with other smaller or non-continuous facilities. In particular, the continuous process flow of the Demo Plant will allow the team to target steady-state operations, and prove Giyani’s ability to produce consistent battery-grade manganese to potential offtake partners, as well as the ability to satisfy offtake requirements.

The Demo Plant’s ability to operate continuously at this pre-commercial scale will allow Giyani to understand how the Commercial Plant will respond, allowing pre-emptive engineering to de-risk potential issues that could arise during ramp-up and operations.

Successful construction and operation of the Demo Plant will, therefore, demonstrate the inherent value of the project to investors. The value of this facility as a tool to optimize our proprietary flowsheet and reduce operating costs is immeasurable and will ultimately advance Giyani’s development as a producer of high-grade manganese for the EV battery market. We look forward to providing further updates on its progress.”

Demo Plant Construction Update

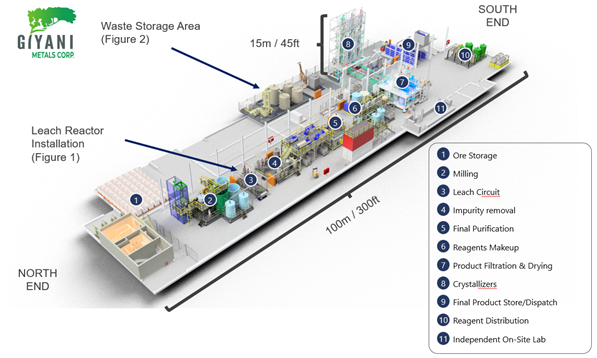

The Demo Plant construction process follows a set order of Process Module installation to ensure a straightforward construction process. The Demo Plant consists of nine Process Modules, each a self-contained process system within a fixed frame. The Demo Plant has been built from the Crystallizer Units to the ore delivery and ball mill (See Figure 3 for Demo Plant 3D render). Within the Plant, the following progress has been made since the last Demo Plant update in August:

- All Process Modules have been installed. See Figures 1 and 2 for the additional Process Modules.

- All tanks, reactors and agitators (leach tank agitators due shortly) have been installed.

- All ventilation circuits have been installed.

- Cabling for power and instrument signalling is progressing rapidly, and the main 1,000kVA transformer station is powering the construction activities in the lead up to commissioning.

- The process off-gas scrubber unit, which controls atmospheric emissions from the Demo Plant, has been installed.

- Piping installation has commenced on a broad scale across the Demo Plant.

Figure 1: Leach Reactor Installation

Construction and Commissioning Update

Following the installation of the final two Process Modules, the leach reactors have been installed and all large components are now in place. This represents a significant construction milestone, as there are now no further heavy lifts to undertake.

Figure 2: Waste Storage Area, with Scrubber in Foreground

The Demo Plant is designed at a scale factor of around 1:10 to the planned Commercial Plant. This provides robust and reliable scale-up from the Demo Plant data when the Commercial Plant is implemented. To illustrate, the leach tanks have a 60cm diameter in the Demo Plant and this is expected to be 8-10x larger at approximately 5m in the Commercial Plant.

Figure 3: Demo Plant Render

The construction program takes advantage of sequential mechanical, piping, electrical, and instrumentation installation to allow cold commissioning to follow the Process Module installation sequence in a highly efficient manner.

With the completion of mechanical equipment installation, the next stages of piping, instrumentation and wiring installation are progressing rapidly. Following the completion of C1 certification (see “Stages of commissioning” below), the exciting process of C2 and C3 commissioning can commence. These stages can be undertaken at an individual Process Module level, as units become available. Commissioning of the full process flow (C4 & C5) will commence once all the individual Process Modules are ready.

Stages of commissioning:

- C1 – Full mechanical completion (individual Process Modules)

- C2 – Dry testing, direction testing, loop testing (individual Process Modules)

- C3 – Cold/Water Commissioning, software testing (individual Process Modules)

- C4 – Hot Commissioning with reagents and steam (full Process)

- C5 – Production Ramp-up (full Process)

The commissioning process will be led by Desiree Meyer, Giyani’s Lead Process Engineer. Desiree has extensive experience in commissioning hydrometallurgical facilities across Africa. Desiree will lead the Minopex operations team in these efforts. By working through commissioning, Minopex will rapidly develop its familiarity with the facility, making Demo Plant production operations safer and more efficient.

Demo Plant Operations Update

Giyani is continuing with software developments on the Yokogawa DCS software that will be used to operate Giyani’s fully continuous Demo Plant. The ability to continuously operate at this pre-commercial scale will allow Giyani to understand how the Commercial Plant will respond ahead of construction, minimizing issues that could arise during ramp-up and operations. Unlike a lab- or pilot-scale operation, a full, industrial control system is required to operate this large-scale, automated, hydrometallurgical plant.

The development of all process standard operating procedures (“SOPs“) is now complete. As the Demo Plant is a duplicate of the anticipated Commercial Plant, the overall operating requirements and system requirements are very similar. Alongside the engineering, commercial and research benefits of the Demo Plant, the development of SOPs will facilitate a smooth transition to full-scale production.

Finalization of the contract for the on-site, independent, ISO-certified, hydrometallurgical laboratory is imminent. This laboratory, which includes ICP-OES and XRF equipment, will allow full commercial-level metal accounting and provide rapid assay turnaround times to enable effective operation of the Demo Plant.

About Giyani

Giyani is focussed on becoming the dominant western-world producer of sustainable, low carbon high purity battery grade manganese for the electric vehicle (“EV“) industry. The Company has developed a proprietary hydrometallurgical process to produce battery grade manganese (HPMSM), a lithium-ion battery cathode precursor material critical for EVs.

The Company has secured financing of US$26m from two strategic partners, ARCH Sustainable Resources Fund LP and the Industrial Development Corporation of South Africa, enabling it to progress the K.Hill battery-grade manganese project in Botswana to construction by building and operating the Demo Plant and completing a Definitive Feasibility Study in 2025.

Additional information and corporate documents may be found on www.sedarplus.ca and on Giyani Metals Corp. website at https://giyanimetals.com/.

About Minopex

Minopex is a global leader in plant operations and maintenance, employing over 2,000 personnel across different operations. With nearly three decades of experience, Minopex has collectively operated some 50 different processing facilities as well as having commissioned and ramped-up over 90 globally, establishing itself as a leader in a variety of minerals processing technologies. For more information about Minopex, visit: www.minopex.com.

About CM Solutions

CM Solutions is a dynamic metallurgical laboratory and consultancy that executes test-work, and goes further to interpret it, model it, and incorporate the results into customer-specific metallurgical designs via an integrated team approach. CM Solutions is a certified ISO 9001:2015 and 14001:2015 company with over 300 clients in the minerals and mining industry across five continents.

Qualified Persons / NI 43-101 Disclosures

A National Instrument 43-101 (“NI 43-101“) technical report including results of the PEA and the MRE can be found on SEDAR+ at www.sedarplus.ca and made available on the Company’s website at https://giyanimetals.com/.

Mr. Justin Taylor CEng FIMMM QMR BSc Eng (Chem) is a qualified person, as defined by NI 43-101. Mr. Taylor is the Company’s Group Process Engineer and has reviewed and approved the scientific and technical content contained in this news release but is not independent for the purposes of NI 43-101.

On behalf of Giyani Metals Corp.

Charles FitzRoy, President and CEO

Contact:

Charles FitzRoy, President & CEO

Tel: +1289-291-7632

Neither the TSX Venture Exchange (the “TSXV”) nor its Regulation Services Provider (as that term is defined in the policies of the TSXV) accepts responsibility for the adequacy or accuracy of this news release.

The securities described herein have not been registered under the United States Securities Act of 1933, as amended (the “U.S. Securities Act”), or any state securities laws, and accordingly, may not be offered or sold to, or for the account or benefit of, persons in the United States or “U.S. persons,” as such term is defined in Regulation S promulgated under the U.S. Securities Act (“U.S. Persons”), except in compliance with the registration requirements of the U.S. Securities Act and applicable state securities requirements or pursuant to exemptions therefrom. This news release does not constitute an offer to sell or a solicitation of an offer to buy any of the Company’s securities to, or for the account of benefit of, persons in the United States or U.S. Persons.

Forward Looking Information

This news release contains “forward-looking information” within the meaning of applicable Canadian securities legislation. All statements in this news release, other than statements of historical fact, that address events or developments that Giyani expects to occur, are “forward-looking statements”. Forward-looking statements are statements that are not historical facts and are generally, but not always, identified by the words “expects”, “does not expect”, “plans”, “anticipates”, “does not anticipate”, “believes”, “intends”, “estimates”, “projects”, “potential”, “scheduled”, “forecast”, “budget” and similar expressions, or that events or conditions “will”, “would”, “may”, “could”, “should” or “might” occur.

Such statements include without limitation: the Company the ongoing construction, commissioning and operation of the Demo Plant, and timing thereof, completion and timing of the DFS or at all.

All such forward-looking statements are based on the opinions and estimates of the relevant management as of the date such statements are made and are subject to certain assumptions, important risk factors and uncertainties, many of which are beyond Giyani’s ability to control or predict. Forward-looking statements are necessarily based on estimates and assumptions that are inherently subject to known and unknown risks, uncertainties and other factors that may cause actual results, level of activity, performance or achievements to be materially different from those expressed or implied by such forward-looking statements. In the case of Giyani, these facts include anticipated operations in future periods, planned construction and development of its properties and facilities, and plans related to its business and other matters that may occur in the future. This information relates to analyses and other information that is based on expectations of future performance and planned work programs.

Forward-looking information is subject to a variety of known and unknown risks, uncertainties and other factors which could cause actual events or results to differ from those expressed or implied by the forward-looking information, including, without limitation: inherent exploration hazards and risks; risks related to exploration and development of natural resource properties; uncertainty in Giyani’s ability to obtain funding; commodity price fluctuations; recent market events and conditions; risks related to governmental regulations; risks related to obtaining necessary licences and permits; risks related to Giyani’s business being subject to environmental laws and regulations; risks related to the Company’s mineral properties being subject to prior unregistered agreements, transfers, or claims and other defects in title; risks relating to competition from larger companies with greater financial and technical resources; risks relating to the inability to meet financial obligations under agreements to which they are a party; ability to recruit and retain qualified personnel; and risks related to the Company’s directors and officers becoming associated with other natural resource companies which may give rise to conflicts of interests. This list is not exhaustive of the factors that may affect Giyani’s forward-looking information. Should one or more of these risks and uncertainties materialize, or should underlying assumptions prove incorrect, actual results may vary materially from those described in the forward-looking information or statements.

Giyani’s forward-looking information is based on the reasonable beliefs, expectations and opinions of the Company’s respective management on the date the statements are made, and Giyani does not assume any obligation to update forward looking information if circumstances or management’s beliefs, expectations or opinions change, except as required by law. For the reasons set forth above, investors should not place undue reliance on forward-looking information. For a complete discussion with respect to Giyani and risks associated with forward-looking information and forward-looking statements, please refer to Giyani’s continuous disclosure documents which are filed on SEDAR+ at www.sedarplus.ca.

Photos accompanying this announcement are available at

https://www.globenewswire.com/NewsRoom/AttachmentNg/b4f3c270-8a56-4fd3-a057-c5f2cb5483ee

https://www.globenewswire.com/NewsRoom/AttachmentNg/8a4c4259-32cf-4bc8-9375-6ca166ffe46d

https://www.globenewswire.com/NewsRoom/AttachmentNg/5c47ec2c-c761-4136-a68e-2f8eccb70399

COMTEX_458148317/2471/2024-09-25T07:02:06